Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

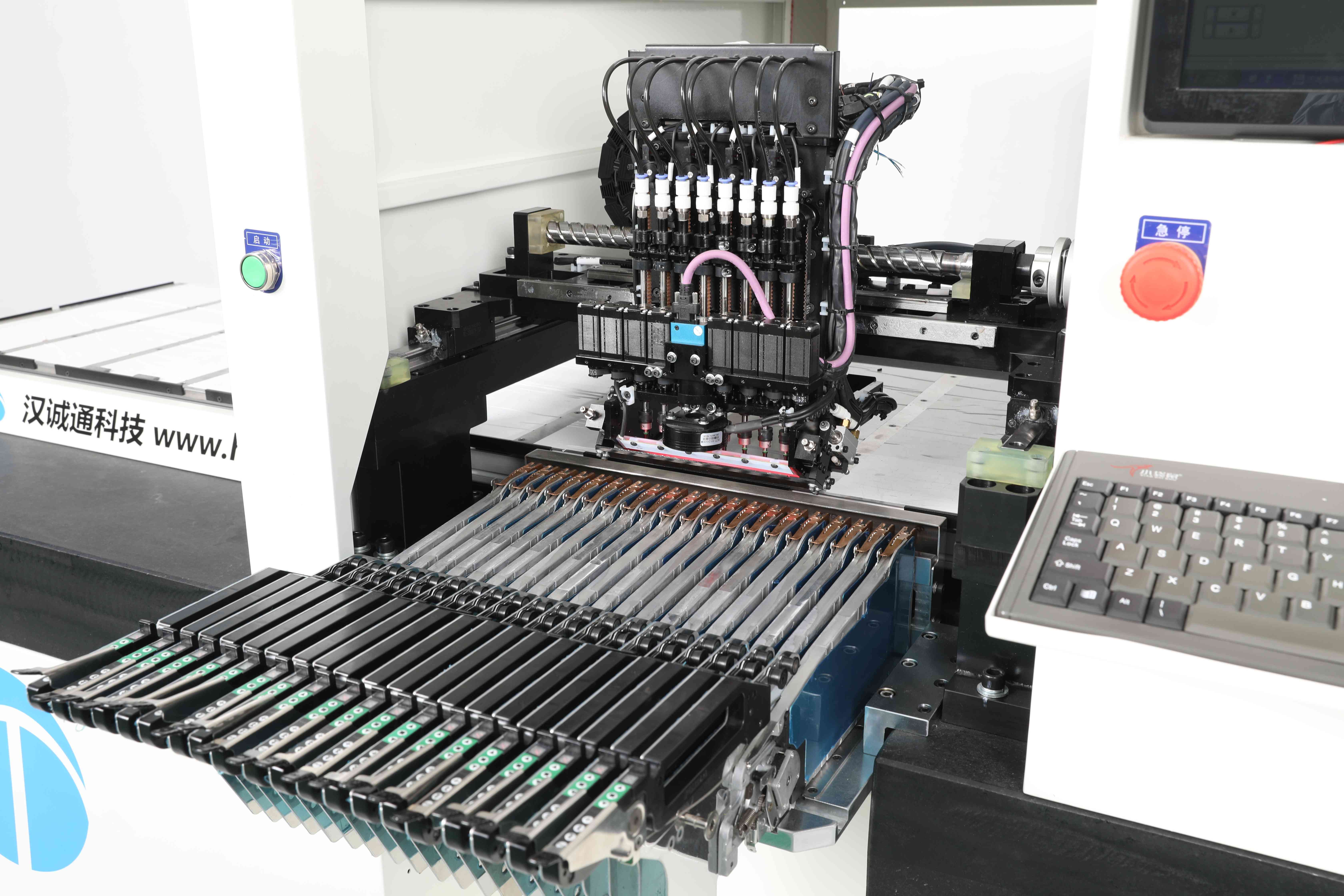

HCT-530SV Semi-auto 8 Heads LED SMD Mounter

The pick and place machine is the most precise and complicated piece of SMT equipment since it is the most crucial part of the SMT manufacturing line. The working environment must meet a number of conditions for the pick and place machine. The slider's service life can be increased and its failure rate can be decreased in a positive work environment.

Technical Parameters - Semi-auto 8 Heads LED SMD Mounter

|

Model |

HCT-530SV |

|

|

Alignment |

Flying Vision Alignment System |

|

|

Number of Spindles |

8 Spindles x 1 Gantry |

|

|

RatedPlacementSpeed |

Vision Alignment |

LED 2835 45,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Mechanical Precision |

±0.02mm |

|

|

Component Range |

VisionAlignment |

0603(inch)~5050~7474(mm), high-power LED,IC<10mm |

|

Max Height |

H=10mm (can handle max. 16mm without vision alignment) |

|

|

Board Dimension(mm) |

Maximum |

1,500(L) x400(W) |

|

Board Handling Method |

Magnetic Fixture Worktable |

|

|

Tape Feeder |

Feeder Type |

Electric Feeder |

|

Feeder Capacity |

20 (12mm) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max2.8KW |

||

|

AirSupply |

Built-in Vacuum Pump |

|

|

Mass |

Approx.1560kg |

|

|

External Dimension(mm) |

2,000(L) x1,250(D) x 1,400(H) |

|

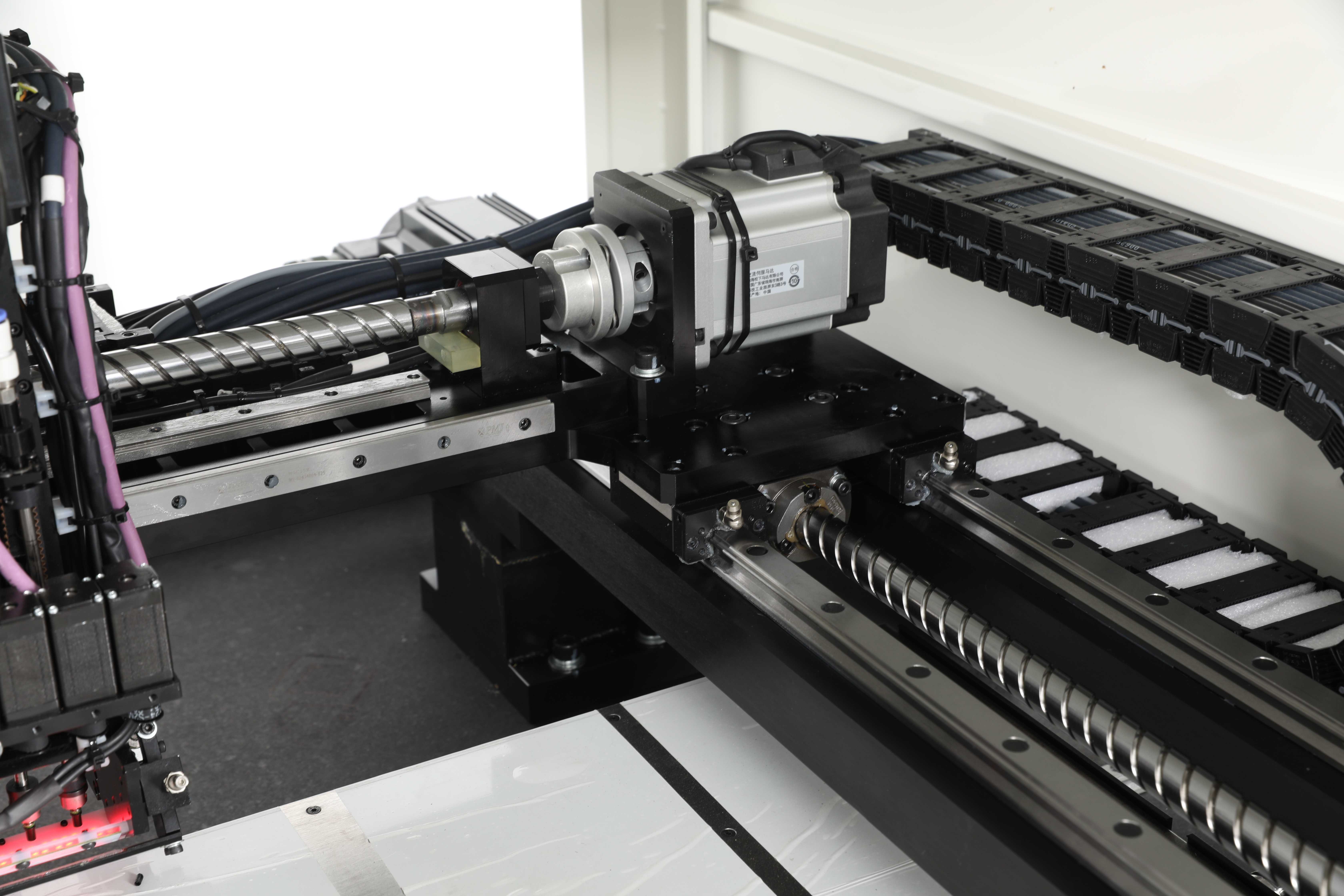

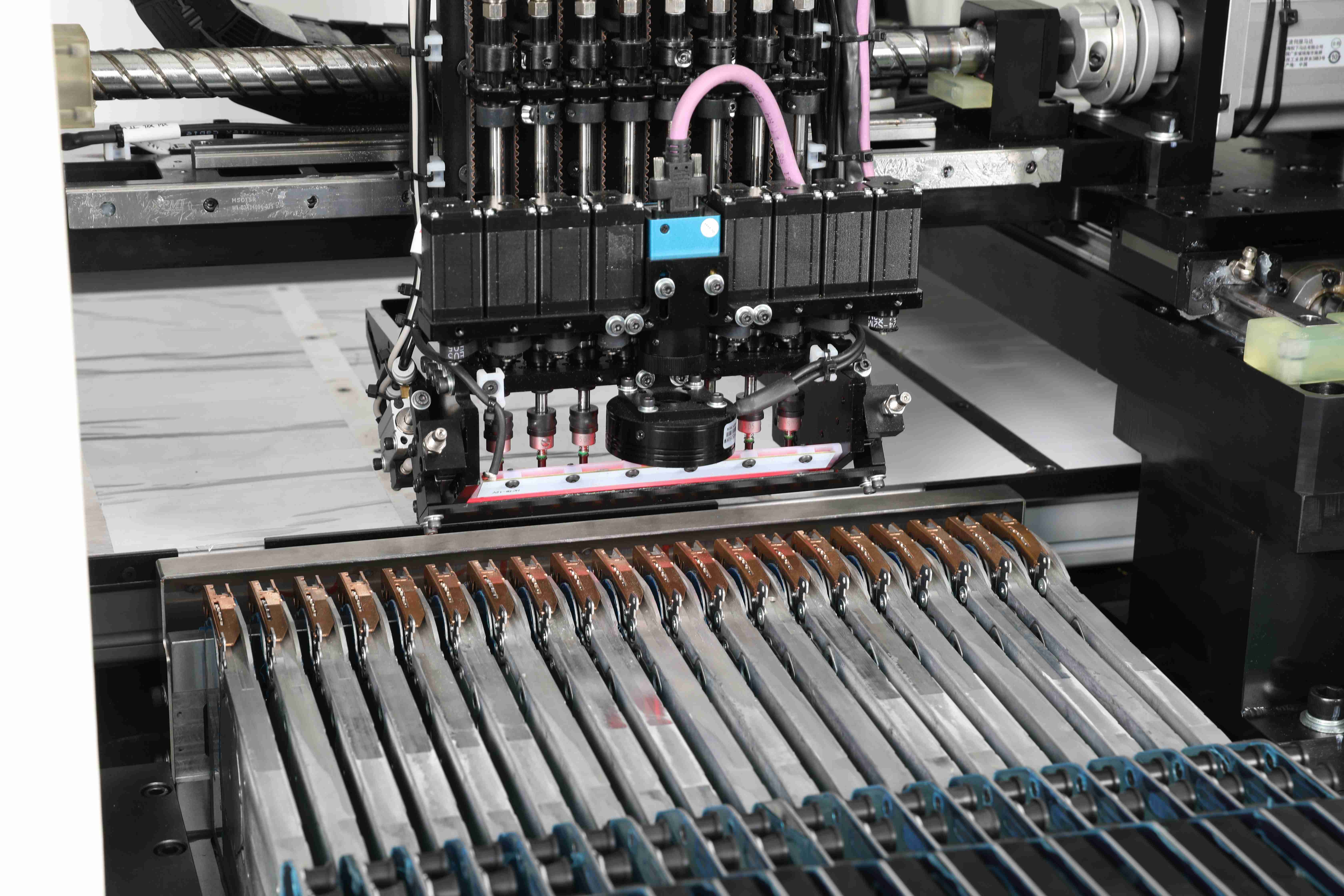

Product Features - Semi-auto 8 Heads LED SMD Mounter

1. High accuracy: Each of the eight pick-up heads is equipped with a FLYING vision alignment camera to guarantee high accuracy.

2. High-speed: Maximum placement speed reaching 0.086s/chip.

3. Each mounting head has its Z - direction closed-loop stepper motor, which is designed for vertical motion.

4. Places SMD components from 0603 to 7474, including resistors, capacitors, and standard and irregularly shaped LEDs.

5. Suitable for all LED lighting products, including flexible PCB strips, circular LED light bulb boards, and even irregularly shaped boards. Assembles LED PCBs up to 1.5 meters long in a single pass.

6. Provide non-stop circulating production for small-size PCBs.

7. Built-in vacuum pump, no outside air source needed.

8. Heavy marble platform support to ensure long service life.

9. Excellent quality hardware support by using international famous brands ensures placement repeatability and precision.

10. Self-developed software simplifies production, easy to operate, and programming.

What Are the Requirements of the Pick &Place Machine for the Working Environment?

The room temperature of the pick and place machine

This is usually best: place the machine and solder paste printing equipment at room temperature 20°C and 26°C, if this number is not reached, no higher than 16°C to 36°C.

The indoor humidity of the pick and place machine

Most people know the impact of space on the pick and place machine, but humidity also has a greater impact on product quality. High humidity components will not absorb moisture, especially internal delicate parts that are humidity sensitive, and if the paste absorbs moisture can also cause solder defects.

One might ask, with humidity having such a big effect, is it okay to try to improve drying? of course not. If the drying is too high, static electricity may be generated when the air dries. Some components, such as electrostatic discharge, are sensitive to static electricity. Therefore, humidity control should also be in equilibrium. Engineer's suggestion: You control the indoor humidity at around 42-73R.

Product Display - Semi-auto 8 Heads LED SMD Mounter